3,427,741,471,176 Pounds of Carbon Dioxide Saved

Projects

- Automated evasive action to start backup equipment when running equipment has failed without operator intervention and maintain the controlled process.

- Control system automatically allows free cooling to run, even during the summer, if ambient conditions are available so as to minimize energy usage.

- Programming in the automation system reduced the energy consumption at an industrial facility to the point where the utility was suspect of its own meter and wanted to change it out.

- Control the process of a utility plant to produce free energy from the temperature difference in ocean water.

- Automation system automatically sheds cooling load to maintain critical cooling for a manufacturing process to complete, thereby saving the product with an estimated street value of $2 million.

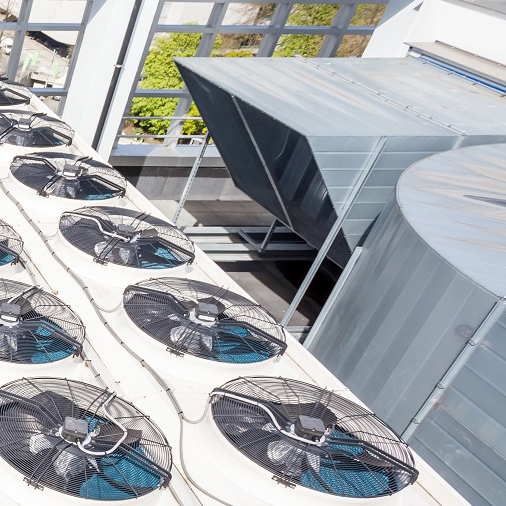

- Automatically optimize the cooling of a data center to reduce PUE while maintaining reliability and uptime.

- Control a 52,000 ton district cooling plant to 0.1 degree Fahrenheit deadband from setpoint while maintaining overall plant efficiency.

- Optimize chilled water plants in the Caribbean by measuring electrical data and running equipment as efficiently as possible.